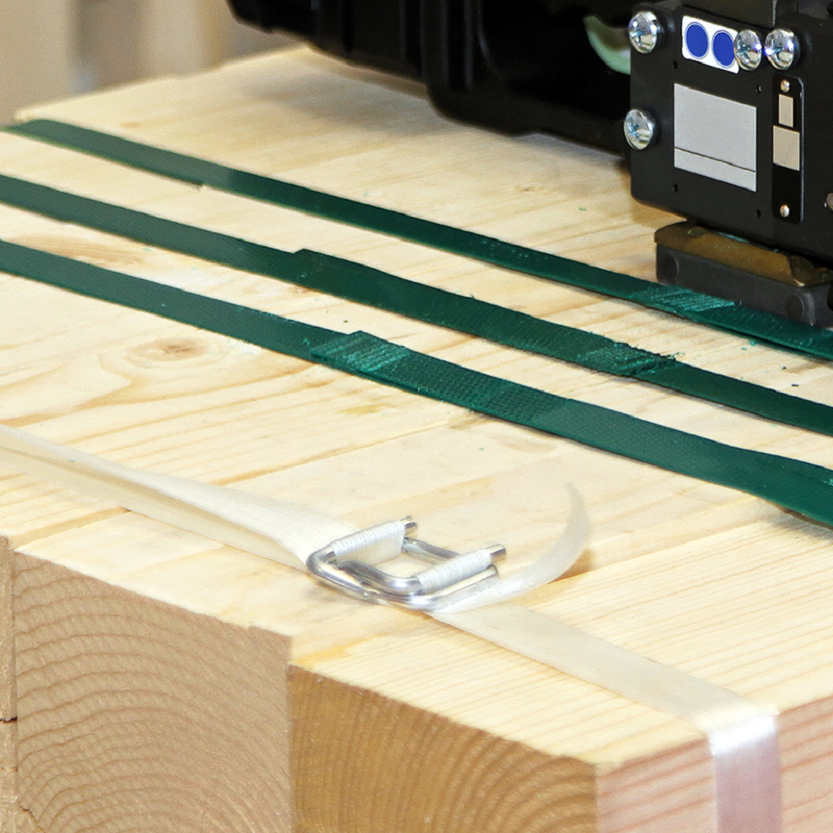

Strapping or what is also known as banding is a process where multiple packets on a pallet are secured with strapping materials using hand tools or machines. Strapping is used in warehouses for securing big pallets of cargo since it allows you to organise items and also keep them from moving or falling during transport. While there are various strapping tools and equipment the most efficient way of securing loads is done by battery strapping but there are certain things you need to be aware of before you get started.

How Strapping Works

Strapping works by tensioning long pieces of steel, polyester or polypropylene material around a pallet of products with a battery strapping tool. When that's done a closure is made so that the items stay in place. On some loads, edge protectors are used on the corners to help spread the tension and reduce damage caused when tensioning the strap.

In order to insert the strap that you've wound up around the load you usually need to squeeze a handle. This opens up a small area underneath the tool where the strap needs to go. If you have the battery powered strapping tool set to auto the tensioning will start automatically and weld the strapping. If you have it set at semi then you need to control the strapping usually by squeezing a handle or pressing a button at your own pace.

At the end you usually need to hold the button for longer in order for the welding to happen. And if you set the device on manual you do the same thing when it comes to tensioning but typically there is a separate button or handle that you need to initiate when you want to weld the strapping.

In order to insert the strap that you've wound up around the load you usually need to squeeze a handle. This opens up a small area underneath the tool where the strap needs to go. If you have the battery powered strapping tool set to auto the tensioning will start automatically and weld the strapping. If you have it set at semi then you need to control the strapping usually by squeezing a handle or pressing a button at your own pace.

At the end you usually need to hold the button for longer in order for the welding to happen. And if you set the device on manual you do the same thing when it comes to tensioning but typically there is a separate button or handle that you need to initiate when you want to weld the strapping.

Benefits

Apart from keeping items from falling and getting damaged strapping is also beneficial for employees too. If the load happens to fall there is also the risk of causing injury to someone. Another benefit is space efficiency, unlike having items scattered around you can store them conveniently without the need for a lot of floor space. One coil of strapping can make for a couple of thousand meters of material whilst taking up way less space.

Strapping Material

Steel

The toughest and oldest strapping material and the one with the highest tensile strength is steel. Steel strapping is used to secure heavy-duty loads and where a lot of stretch is not required, sharp edges are present as well as rough surfaces.

Polypropylene

Polypropylene may not be as strong as steel but it is a very light and versatile material which doesn't corrode and can resist scrapes and bumps. Polypropylene strapping won't deform and it is elastic. This makes it ideal for securing, sealing and reinforcing lighter loads which are going to be stored for long periods of time and/ or shipped across long distances.

Extruded Polyester

What is also known as PET, extruded polyester is the strongest plastic strapping and unlike steel it has a little bit of flex to it. Extruded polyester is resistant to UV rays and moisture. This makes polyester another ideal long-term solution which you can use to seal heavier loads than what you would use polypropylene for. This strapping is made of 80% recycled material so it's more eco-friendly than other plastic options.

Corded Polyester

Another strapping material that is high in strength is corded polyester which is used to seal fragile and delicate products. It's a light material that won't rot or rust and it doesn't leave marks. This material is best used with hand tools such as sealers and tensioners.

How to Maintain Your Battery Strapping Tool

You or your employees should always look after the battery powered strapping tool and keeping it dust free is one great way to do so. After every shift or using the tool its recommended that the you wipe it down using a clean dry cloth. Otherwise fine dust can easily cause jams over time and a few minutes everyday is all it takes to prevent that.

A good step in the right direction when it comes to preventative maintenance is adequate training for your employees. With proper training it's less likely that the device will get misused and damaged. In case issues were to occur employees can fix them on their own when they know how the device operates. Proper training will also make them more efficient and less likely to make mistakes.

Recalibrating and adjusting is part of the job too and although it is not as much of an everyday task as strapping itself, it is still a crucial part. The more the tool is used the more parts tend to wear out and need to be replaced or realigned by tightening fasteners. This is why testing is another part of preventative maintenance in a battery operated strapping tool. This will ensure that any issues don't go undetected and that the device is in an operational state.

A good step in the right direction when it comes to preventative maintenance is adequate training for your employees. With proper training it's less likely that the device will get misused and damaged. In case issues were to occur employees can fix them on their own when they know how the device operates. Proper training will also make them more efficient and less likely to make mistakes.

Recalibrating and adjusting is part of the job too and although it is not as much of an everyday task as strapping itself, it is still a crucial part. The more the tool is used the more parts tend to wear out and need to be replaced or realigned by tightening fasteners. This is why testing is another part of preventative maintenance in a battery operated strapping tool. This will ensure that any issues don't go undetected and that the device is in an operational state.