Metal fabrication is a procedure which involves cutting, shaping raw metal materials. There are three basic categories: commercial, industrial and structural fabrication. Each of these provides different services that are aimed for different industries.

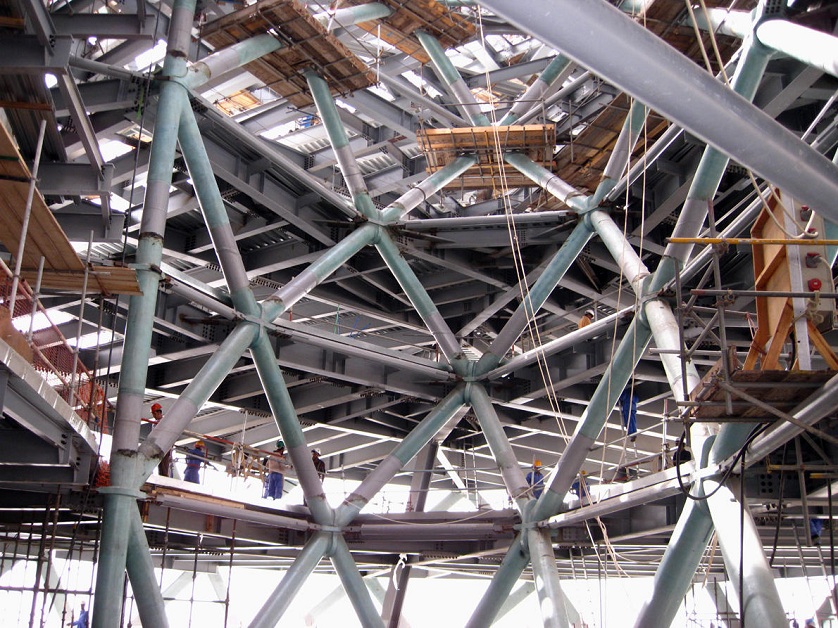

Structural metal fabrication is widely used and provides many benefits. It is the process of creating metal components that are used to build structures and it represents an important part of the manufacturing process for any building and construction company. The actual process of structural metal fabrication includes a wide range of methods that are used to assemble all the cut and shaped pieces of metal. Furthermore, many tools are required to get the final product, from cutting torches and band saws to various plasma and laser cutters.

Besides various different tools, the process of metal fabrication also incorporates many different types of raw materials. These include fittings, welding wires, plate metals, castings, section metals as well as various kinds of hardware. Skilled and experienced technicians are required to assemble all the raw components together and provide high-quality and efficient structural metal fabrication services.

When it comes to quality and successful manufacturing process, metal fabricators make use of different machines and equipment to provide reliable and precisely finished structures. Moreover, there are many methods and techniques that are essential for producing high-quality final products. Here are the most commonly used procedures during the assembly process.

Cutting metal

The cutting procedures involves various methods that are used to cut the metal to the desired size. The manual method involves head sherds as the basic tool. However, power shears, plasma cutters as well as electric angle grinders are commonly used these days since they provide great precision. Also, these tools are designed to cut metal quickly and with minimal effort.

Welding metal

Welding is the process of fusing two pieces of metal together. It involves applying both heat and pressure to the base metal. During the procedure a filler rod is added in order to create a weld pool which is than cooled and forms a strong metal fusion. Various different types of welding are used, from the manual stick welding to the advanced robot welding, fabricator employ different methods in the structural metal fabrication.

Bending metal

The easiest way used to bend metal is form bending. The bending is done over an edge or special shape that is placed underneath the flat piece of metal. This method includes tools like shaping dollies or hammers that are used to bend the metal around the desired shape. However, when it comes to clean, precise bends the best tool is the metal brake which can bend the metal to the different angles.

Besides various different tools, the process of metal fabrication also incorporates many different types of raw materials. These include fittings, welding wires, plate metals, castings, section metals as well as various kinds of hardware. Skilled and experienced technicians are required to assemble all the raw components together and provide high-quality and efficient structural metal fabrication services.

When it comes to quality and successful manufacturing process, metal fabricators make use of different machines and equipment to provide reliable and precisely finished structures. Moreover, there are many methods and techniques that are essential for producing high-quality final products. Here are the most commonly used procedures during the assembly process.

Cutting metal

The cutting procedures involves various methods that are used to cut the metal to the desired size. The manual method involves head sherds as the basic tool. However, power shears, plasma cutters as well as electric angle grinders are commonly used these days since they provide great precision. Also, these tools are designed to cut metal quickly and with minimal effort.

Welding metal

Welding is the process of fusing two pieces of metal together. It involves applying both heat and pressure to the base metal. During the procedure a filler rod is added in order to create a weld pool which is than cooled and forms a strong metal fusion. Various different types of welding are used, from the manual stick welding to the advanced robot welding, fabricator employ different methods in the structural metal fabrication.

Bending metal

The easiest way used to bend metal is form bending. The bending is done over an edge or special shape that is placed underneath the flat piece of metal. This method includes tools like shaping dollies or hammers that are used to bend the metal around the desired shape. However, when it comes to clean, precise bends the best tool is the metal brake which can bend the metal to the different angles.