Manufacturers working with plastic and producing plastic parts know best; there's a huge difference between plastic molding and plastic machining, as the two main processes for making plastic products. Parts produced with the two separate processes differ much in various aspects: price, quality, shape and use. Here's where the difference lies:

Definition:

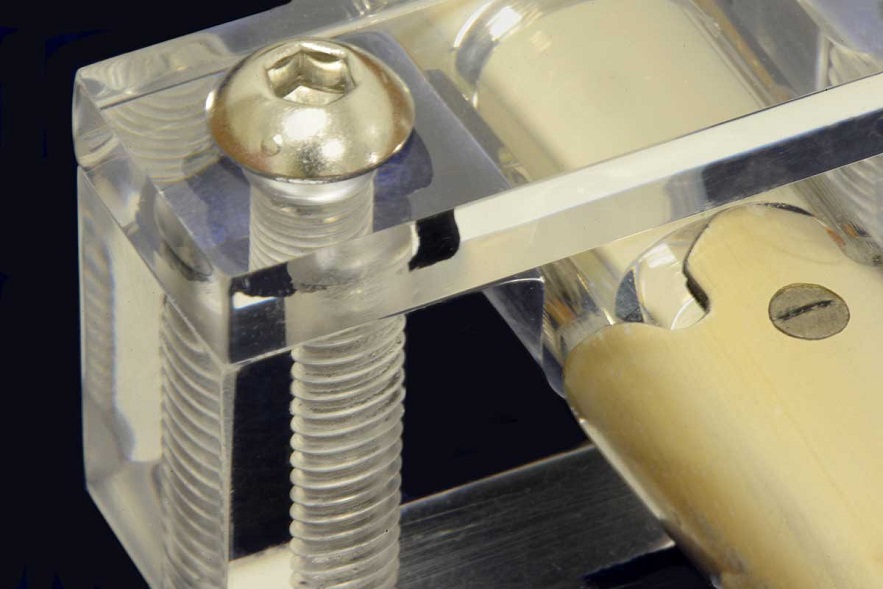

Plastic injection molding is performed with plastic pellets. These pellets are rigid when cool, but viscous when at higher temperatures. In order to be used in the process, these are heated till melting point and as such are injected into a cavity. While slowly cooling down, they take the cavity's shape. Plastic machining on the other hand is a process of cutting material from another larger piece of plastic and then shaping this piece with a knife or special scissors.

Price:

Although the same purpose, plastic injection molding and plastic machining don't belong in the same price range. Plastic machining is a lot more expensive and can cost up to 25 times more than plastic molding. However, there are cases when plastic machining can be done for a lot less money, like if you need only a few parts. The moment that creates the huge discrepancy in price is the initial mold. Creating the initial mold can cost up to $200000, depending on the level of complexity. Molding on the other hand is a whole different story, but if you only need to make a few parts, the initial cost of $10000 for the mold can turn out to cost you more than simply machining the parts.

Characteristics:

Plastic machining is far more precise than plastic molding. Molding can give you results up to 0.013 centimeters precision, while machining can provide up to 0.0025 centimeters of precision. And there's surface smoothness. If you need a part with exceptional surface smoothness, you should go with plastic machining, since plastic molding creates a piece with a slight surface imperfection as a result of transferring the plastic into the mold. When plastic is melted and transferred into the mold, it flows through runners and than gets into the cavity. As a melted mass, the surface it creates in the cavity isn't straightened, and imperfections often occur. So if you need parts that are blemish free, it's strongly recommended to go with plastic machining instead of injection molding.

Whether you're a manufacturer or you simply need the service, always make the plan before you start searching for the best option. If you need only a few parts to be produced, than go with plastic machining; it's cheaper and more precise. Plastic molding is a good option if you're in need of large pieces that don't necessarily need to fit perfectly somewhere.

Plastic injection molding is performed with plastic pellets. These pellets are rigid when cool, but viscous when at higher temperatures. In order to be used in the process, these are heated till melting point and as such are injected into a cavity. While slowly cooling down, they take the cavity's shape. Plastic machining on the other hand is a process of cutting material from another larger piece of plastic and then shaping this piece with a knife or special scissors.

Price:

Although the same purpose, plastic injection molding and plastic machining don't belong in the same price range. Plastic machining is a lot more expensive and can cost up to 25 times more than plastic molding. However, there are cases when plastic machining can be done for a lot less money, like if you need only a few parts. The moment that creates the huge discrepancy in price is the initial mold. Creating the initial mold can cost up to $200000, depending on the level of complexity. Molding on the other hand is a whole different story, but if you only need to make a few parts, the initial cost of $10000 for the mold can turn out to cost you more than simply machining the parts.

Characteristics:

Plastic machining is far more precise than plastic molding. Molding can give you results up to 0.013 centimeters precision, while machining can provide up to 0.0025 centimeters of precision. And there's surface smoothness. If you need a part with exceptional surface smoothness, you should go with plastic machining, since plastic molding creates a piece with a slight surface imperfection as a result of transferring the plastic into the mold. When plastic is melted and transferred into the mold, it flows through runners and than gets into the cavity. As a melted mass, the surface it creates in the cavity isn't straightened, and imperfections often occur. So if you need parts that are blemish free, it's strongly recommended to go with plastic machining instead of injection molding.

Whether you're a manufacturer or you simply need the service, always make the plan before you start searching for the best option. If you need only a few parts to be produced, than go with plastic machining; it's cheaper and more precise. Plastic molding is a good option if you're in need of large pieces that don't necessarily need to fit perfectly somewhere.