A refrigeration manifold is a device that is used as a service tool and as a diagnosis tool. This device tests the amount of pressure inside different types of cooling systems. Refrigeration gauge manifolds can be used to service vehicles, check the pressure in refrigerant service machines and remove refrigerants that might be contaminated from the air conditioning system, this prevents the contamination of other machines. A refrigeration gauge manifold should be a part of the toolset of every technician. There are some variations on gauge manifolds from one manufacturer to the other, but they are mainly made up of the same parts.

Not all manifolds are arranged in the same way, but most are, and those who are arranged differently it is usually done for easier identification. If it's necessary for the measurements a refrigerant can be added to the manifold, however adding the refrigerant could be dangerous and under environmental laws, it should be done only by technicians who are qualified. There are also some manifolds that are designed with a small piece of glass on them, this is done, so you or the technician to observe how the refrigerant flows. This is done so you can monitor the amount of refrigerant you add because it must be the right amount.

There are two types of refrigeration manifolds, an analogue and a digital refrigeration manifold. Analog gauges have been used for a long time, many generations of professional cooling and heating technicians have worked with them. The professional technicians who have used analogue gauges can be able to tell everything they just by looking at what the hands tell them, they don't even have to look at the complex charts. However, doing this can turn out to be quite the problem. As the readings on an analogue gauge aren't the perfect ones and if the technician gets it wrong the problem could potentially become a bigger one.

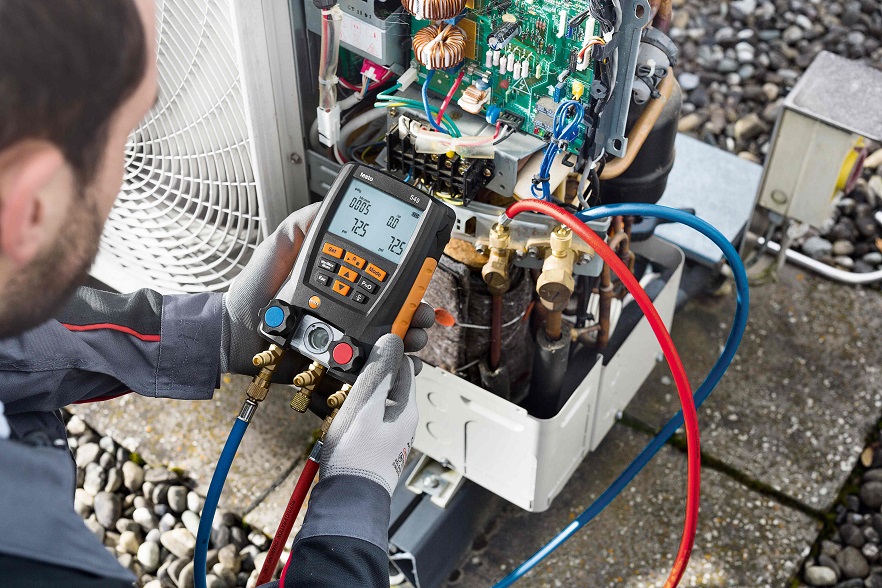

Digital gauges are preferred by many technicians in the modern day and age because they give them results much faster. The results that are given by a digital manifold are also much more reliable and accurate. They also provide a lot of other features and readings, without the need of complicated charts and conversion tables. Meaning, that errors are less likely to occur. The only problems that technicians have found with digital refrigeration manifolds are that they require some training in order to be used properly. If you aren't well trained using models that have other features added to them can confuse you and that could complicate things.

There are two types of refrigeration manifolds, an analogue and a digital refrigeration manifold. Analog gauges have been used for a long time, many generations of professional cooling and heating technicians have worked with them. The professional technicians who have used analogue gauges can be able to tell everything they just by looking at what the hands tell them, they don't even have to look at the complex charts. However, doing this can turn out to be quite the problem. As the readings on an analogue gauge aren't the perfect ones and if the technician gets it wrong the problem could potentially become a bigger one.

Digital gauges are preferred by many technicians in the modern day and age because they give them results much faster. The results that are given by a digital manifold are also much more reliable and accurate. They also provide a lot of other features and readings, without the need of complicated charts and conversion tables. Meaning, that errors are less likely to occur. The only problems that technicians have found with digital refrigeration manifolds are that they require some training in order to be used properly. If you aren't well trained using models that have other features added to them can confuse you and that could complicate things.